Exhaust heat content in convective dryers sensible heating of solids heat losses from dryer body. Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

163 Design of Flash Dryers.

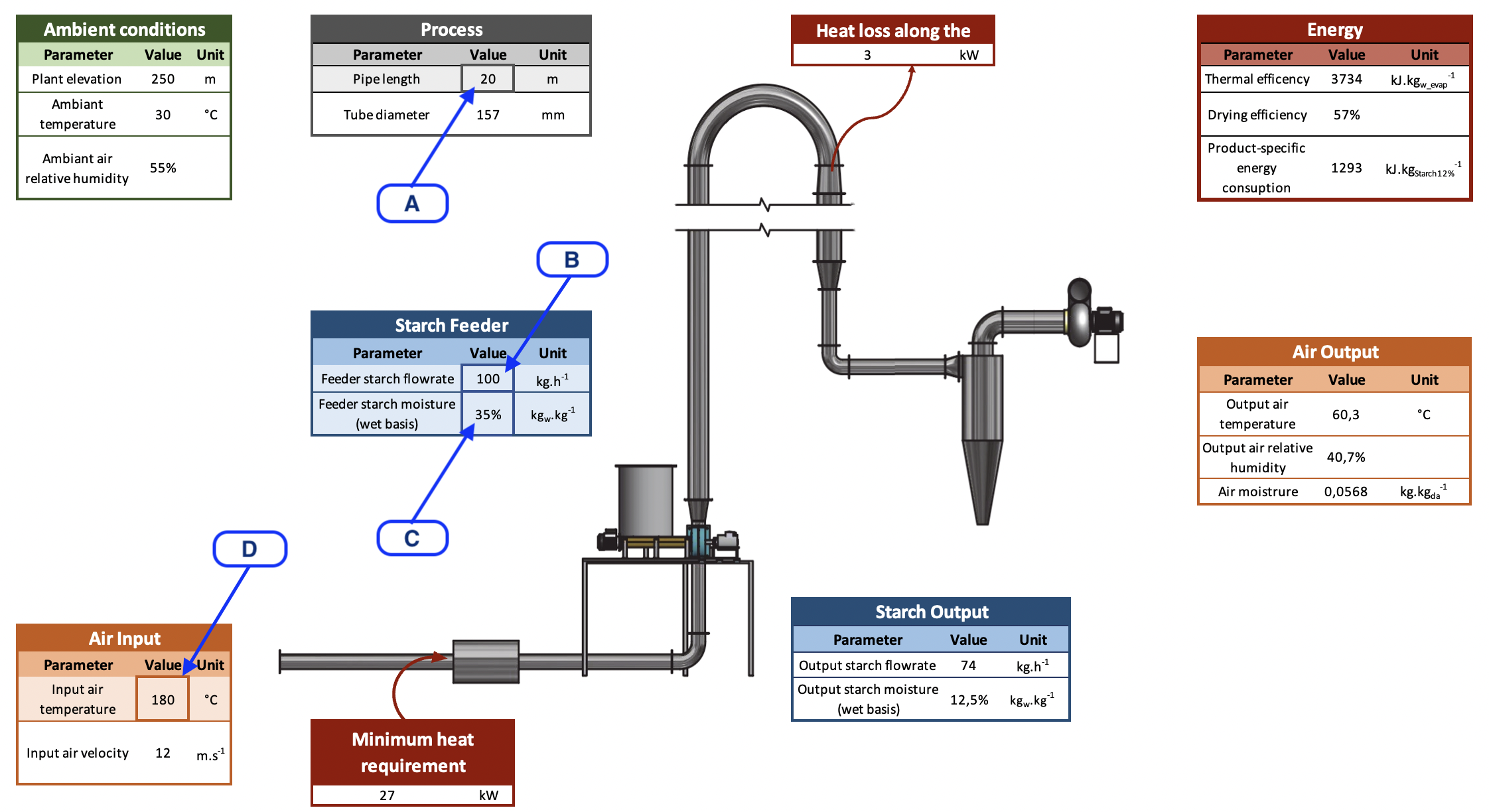

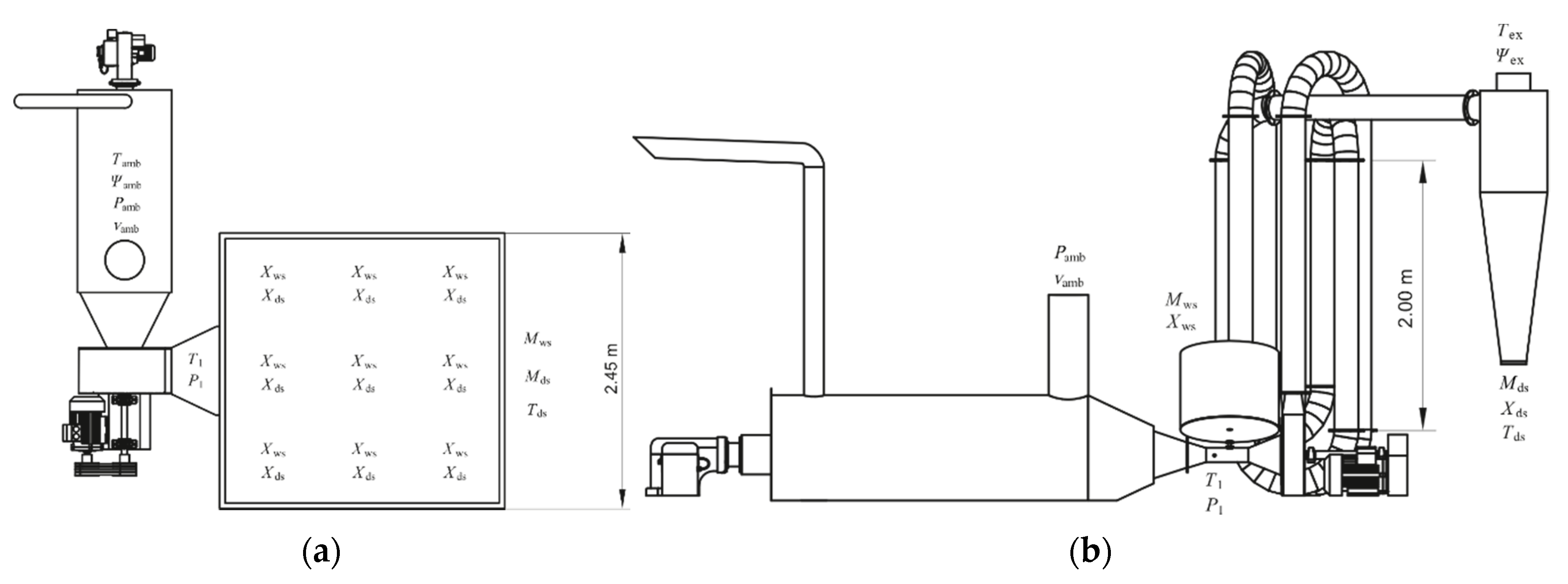

. To the design of extruding and tray-filling equipment for de-watered cakes it is now possible to obtain the maximum benefit of enhanced evaporative rates by using through-air circulation. Design basis The following were the physico-chemical properties of cassava starch used as input variables to determine parameters of interest necessary for the design of a column flash. Process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

Of the numerical calculations were partially compared. 1 Thermal inefficiencies in the dryer. Fluid Electrolyte and Acid-base Balance.

A material moisture content solid line and. Qingdao PALET Machinery can design and manufacture the Rotary Dryer Machine dryer equipment for the customers especially according to the information of material. Capacity based on 10 moisture wet weight in material fed to dryer and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder.

18X18 Flash Drive Dryer Define Design Calculations 110V Find Details about Screen Printing Flash Dryer 220V IR Flash Dryer from 18X18 Flash Drive Dryer Define Design Calculations. Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. With experimental data and the influence of the fric-tion factor on the pressure gas and particle.

Operation typewe will consider either batch. Pdf 6 Pneumatic And Flash Drying Pdf 6 Pneumatic And Flash Drying Diagram Of A Flash Dryer For Pulp According To Svensson 51 Download Scientific Diagram Flash Dryer Design Tools Rtb Scaling Flash Drying. Flash drying is a continuous process with the dryer being either directly or indirectly fired.

Three factors will be considered. Actual measurements and calculations may vary slightly due to different measurement methods within the industry. As per theory thickness can be derived using the formula T P x R S x E - 06 x P P - design pressure R - Inner dia S - allowable stress E.

Ad The Best Selection of Eco-Friendly. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products. They are inherently cocurrent dryers with the hottest air contacting the wettest product.

FIGURE 39 Longitudinal parameter distribution for a cross-flow dryer with one-dimensional solid flow. This tool calculates key parameters of the flash dryer system based on the characteristics of the product to dry feed rate initial moisture content. Ad Get Flash Dryers Equipment Within 24 Hours Or Consult With Industry Experts.

The Design of Spin Flash Dryer JIANG BinCHAI Ben-yinPENG Li-hua MIAO ShuaiDONG Xian-huaZHANG Lei Shandong Tianli Drying Equipment CoLtdJinan 250014China. Let the working pressure be 25 Kgcm2 Vacuum. 2 Thermal inefficiencies in the utility heat supply.

The results prove that the dryer is most efficient when the dryer runs at 370 Kelvin and 03 meters per second when the allotted drying time is less than 217 hours. Continuous process is being started up or shut down the accumulation term is nonzero and the balance 1. Electrical calculations should be made for all SPU projects that.

Vitamins and Minerals Medicines. Heat and mass energy balances in designing a dryer for food applicationsPlease provide feedback on this module by selecting _Like_ or _Dislike_. Screenprinting Supplies Screens.

Input air temperature and pipe length can also be adjusted to probe the energy-efficiency of different operating conditions. If the throughput of the dryer is 60 kg of wet product per hour drying it from 55. 18x18 Flash Drive Dryer Define Design Calculations 110v Find Complete Details about 18x18 Flash Drive Dryer Define Design Calculations 110v18x18 Flash DryerFlash Drive DryerFlash.

Flash Dryer Design Tools Rtb Scaling Flash Drying

Flash Dryer Gea Solid Feed Drying

Pdf 6 Pneumatic And Flash Drying

Flash Dryer Design Tools Rtb Scaling Flash Drying

Flash Dryer Gea Solid Feed Drying

Applied Sciences Free Full Text Comparative Study Between Current Practices On Cassava Drying By Small Size Enterprises In Africa Html

0 comments

Post a Comment